CNC MACHINE TENDING SOLUTION

A Preconfigured Machine Solution To Help You Maximize Your CNC Productivity.

Designed To Easily Interface With Your CNC Mill And Turning Equipment.

CNC Machine Tending Solution

Less time spent loading parts means more time for your machinists to perform value added operations leading to increased productivity.

More spindle uptime with automated tending throughout the day including breaks, after hours, and days off.

Fast ROI - reliable, consistent, machine tending solution that offers a 6 month ROI depending on the number of shifts you run.

MACHINE TENDING SOLUTION FEATURES

LATHE AMS - MTL

Universal Robots UR10E

Heavy Duty Cart For Part Queuing

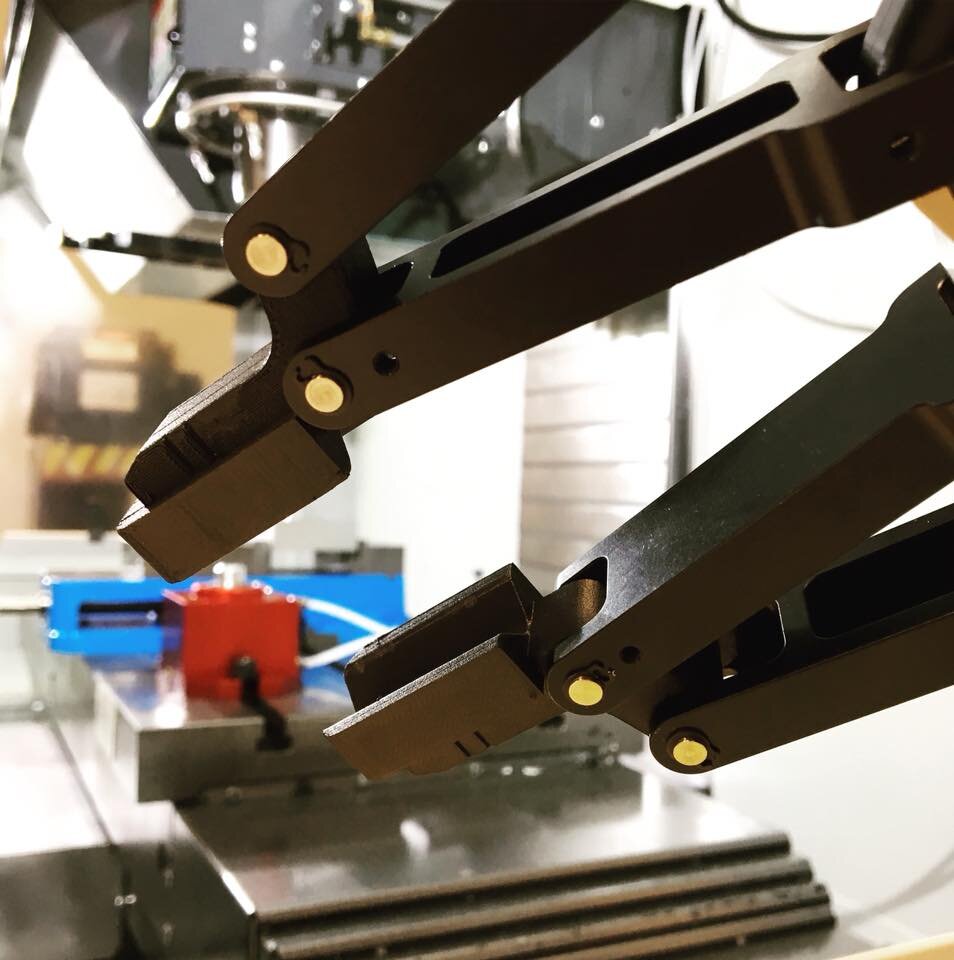

Robotiq 2 Finger Gripper

Programable Air Blowoff

Installation & Training

Setup Of Single Operation Lathe Program

MILL – SINGLE VISE AMS - MTM

Universal Robots Ur10e

Heavy Duty Cart For Part Queuing

Robotiq 2 Finger Gripper

Programable Air Blowoff

Installation & Training

6" Air Vise

Setup Of Single Operation Mill Program

MILL – DUAL VISE AMS - MTM2

Universal Robots UR10E

Heavy Duty Cart For Part Queuing

Robotiq 2 Finger Gripper

Programable Air Blowoff

Installation & Training

2 - 6" Air Vise

Part Flip Station

Setup Of 2 Operation Mill Program

MACHINE TENDING SOLUTION OPTIONS

DUAL GRIPPER

CUSTOM GRIPPERS

SAFETY SCANNERS

PART FLIP STATION

DOOR OPENERS

CUSTOM PROGRAMMING

*Pricing is for standard units. Subject to engineering review. Additional options, safety devices, and customization can be added based on application requirements. Shipping not included. Prices subject to change.*

Looking To Schedule A Machine Tending Readiness Evaluation?